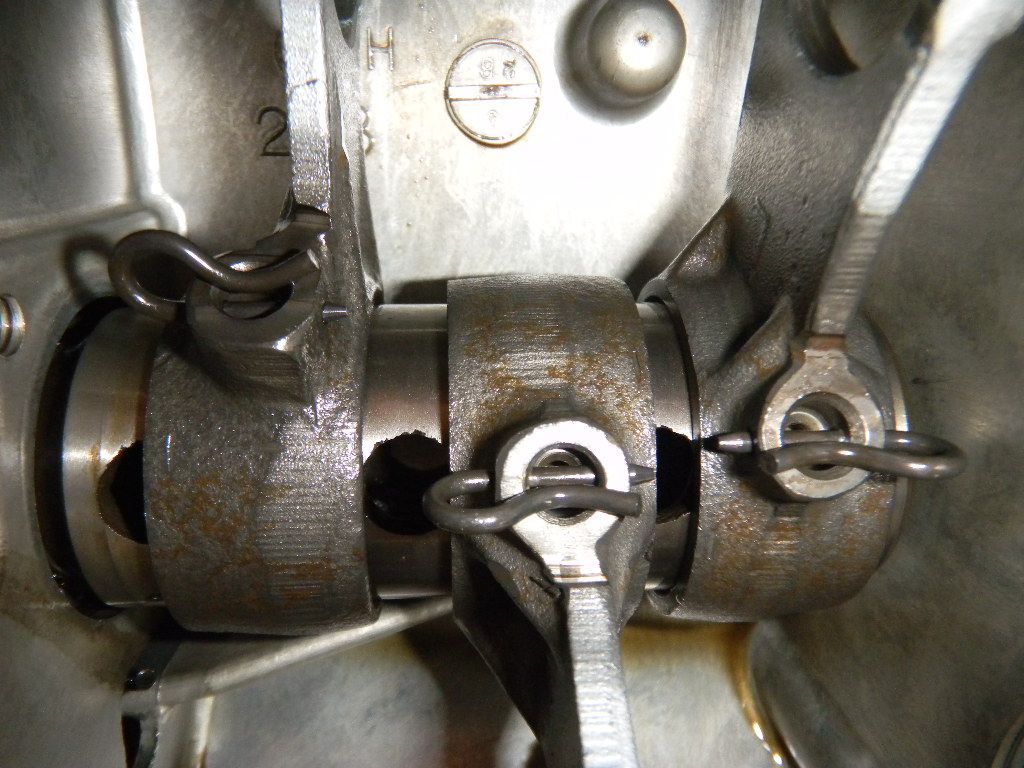

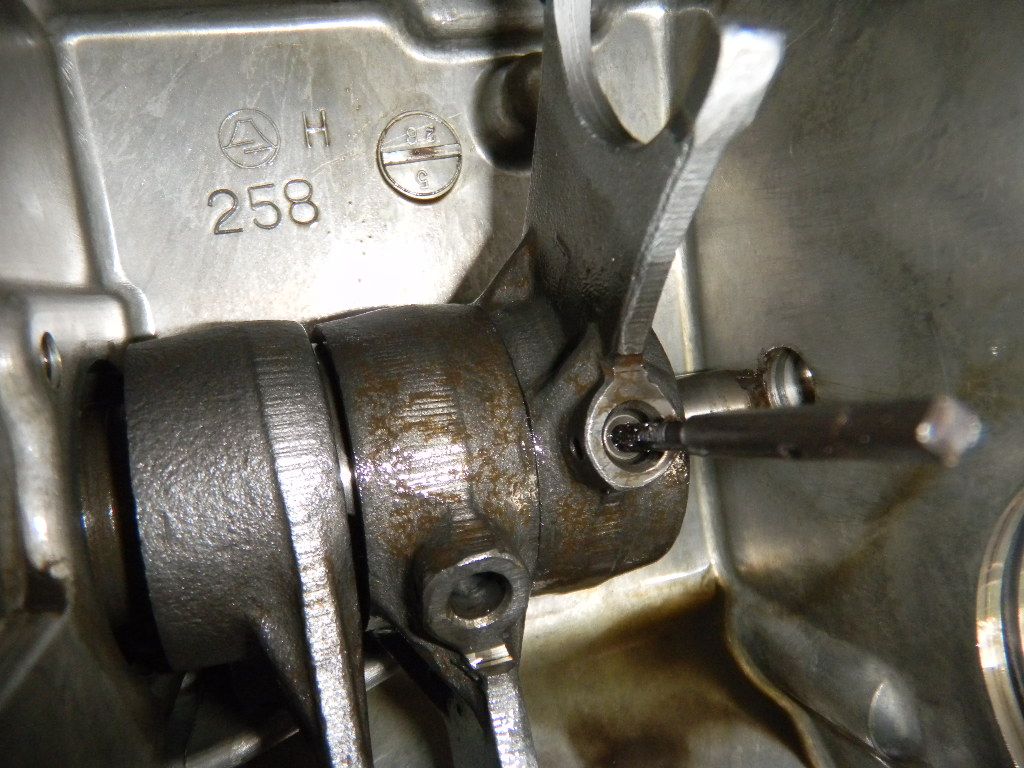

Got this bike about a year ago and finally got time to take her apart. The plan is to keep it stock with OEM parts. It won't be a short term project. Hope to have it done by spring 2013.

Here she is just after I got it. Looks good from 20ft. Attempted to start it and ran on only the left cylinder. Corrected the stuck float valve on the right and it ran. Not good, but it ran

![Image]()

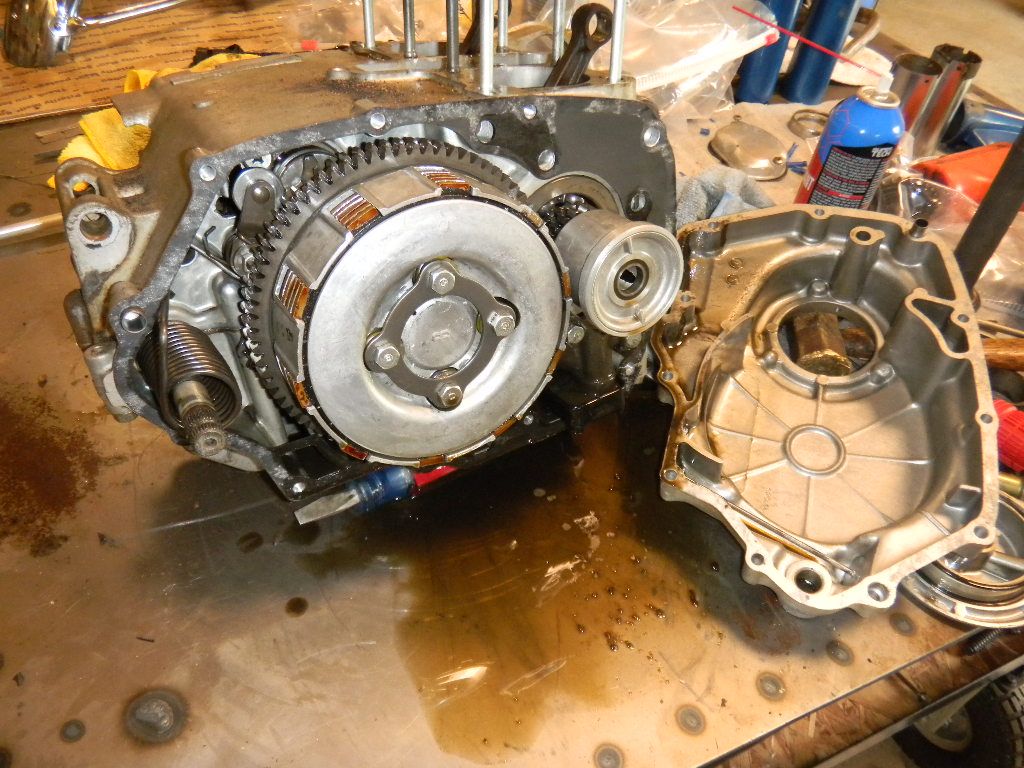

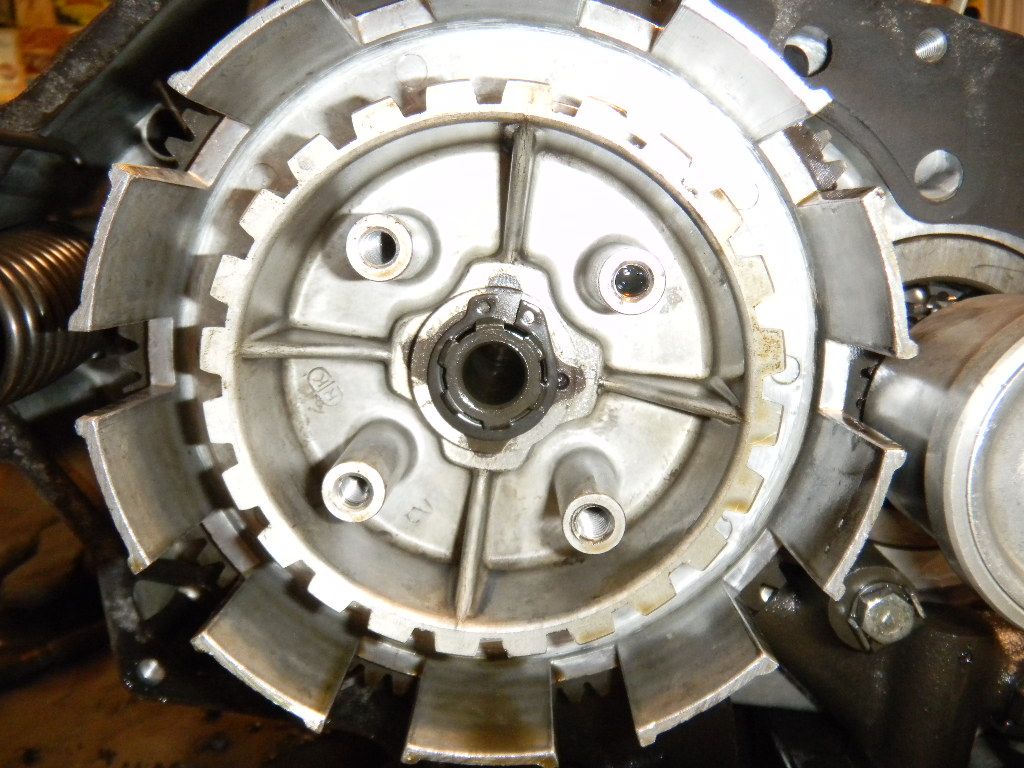

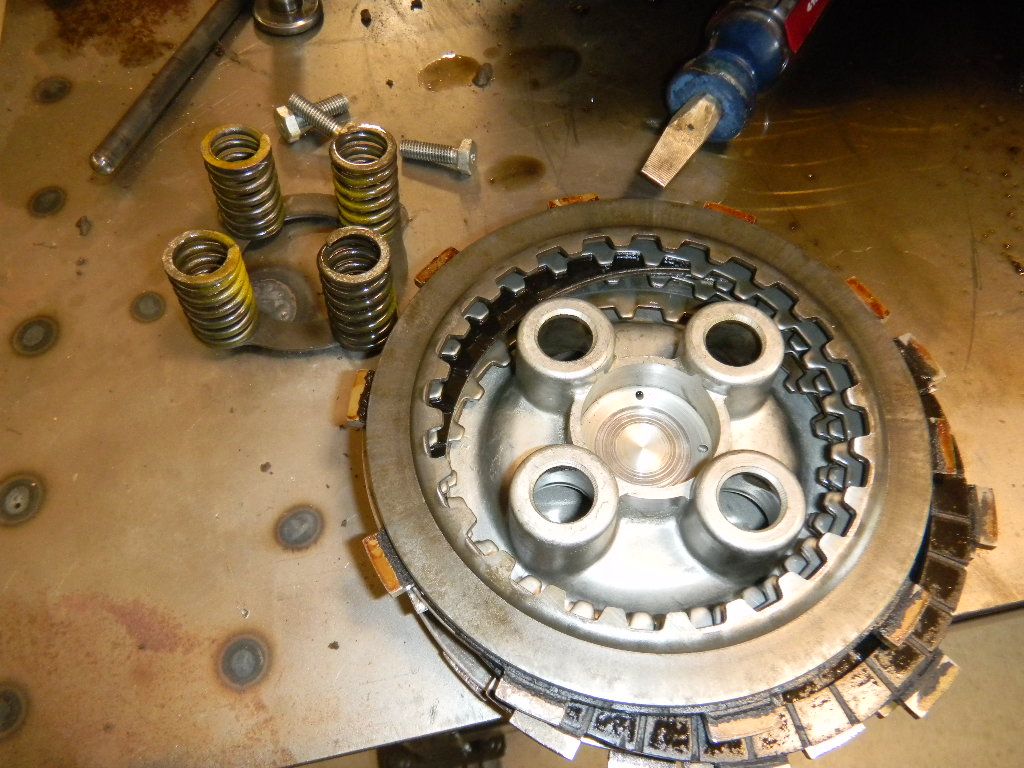

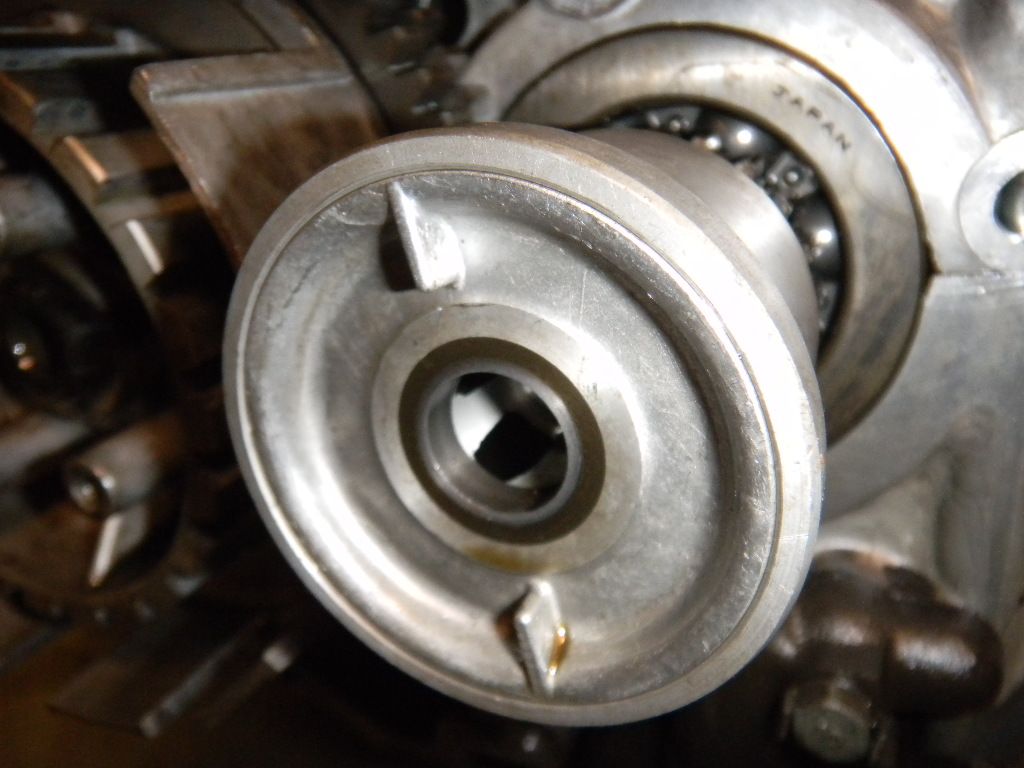

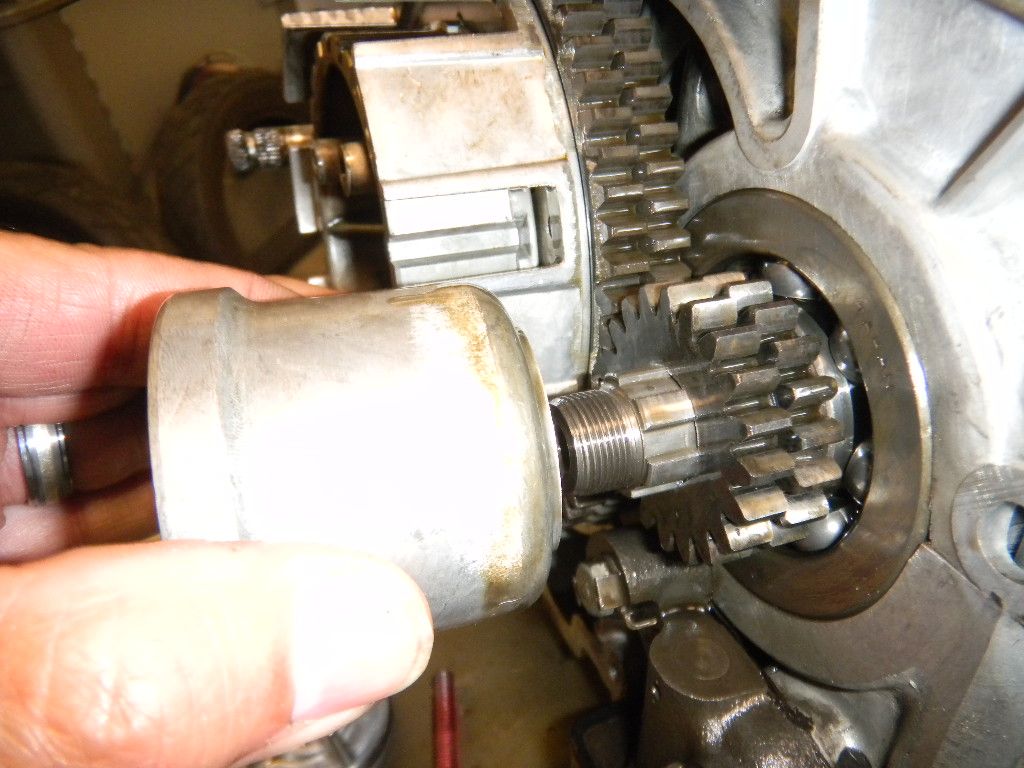

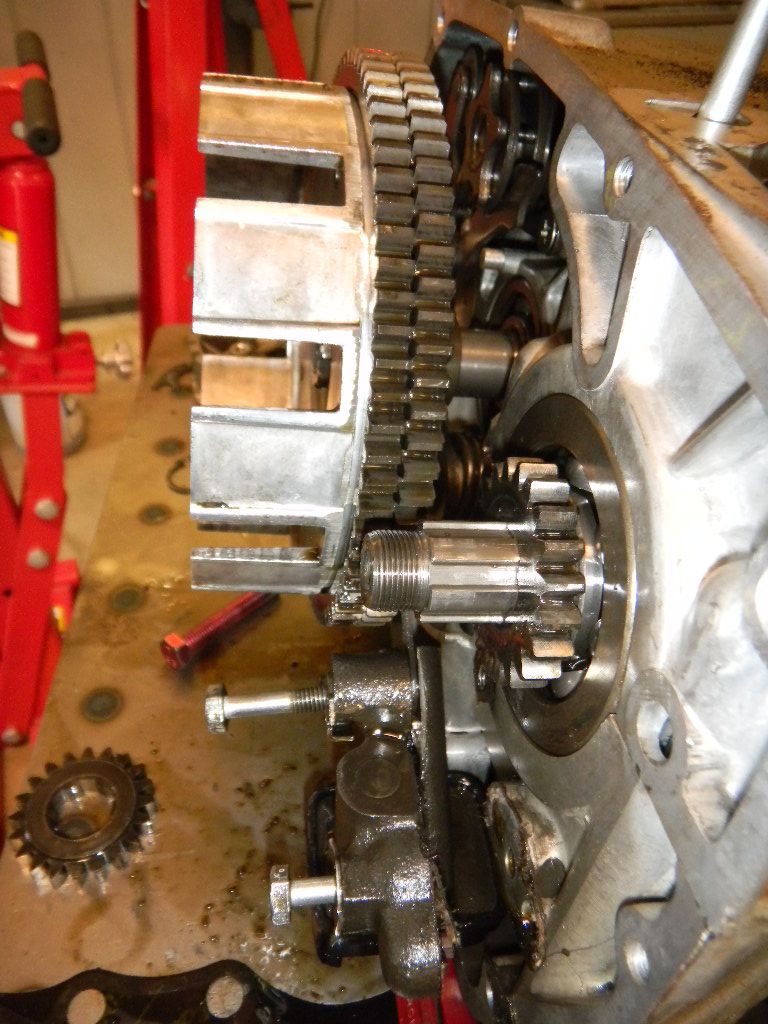

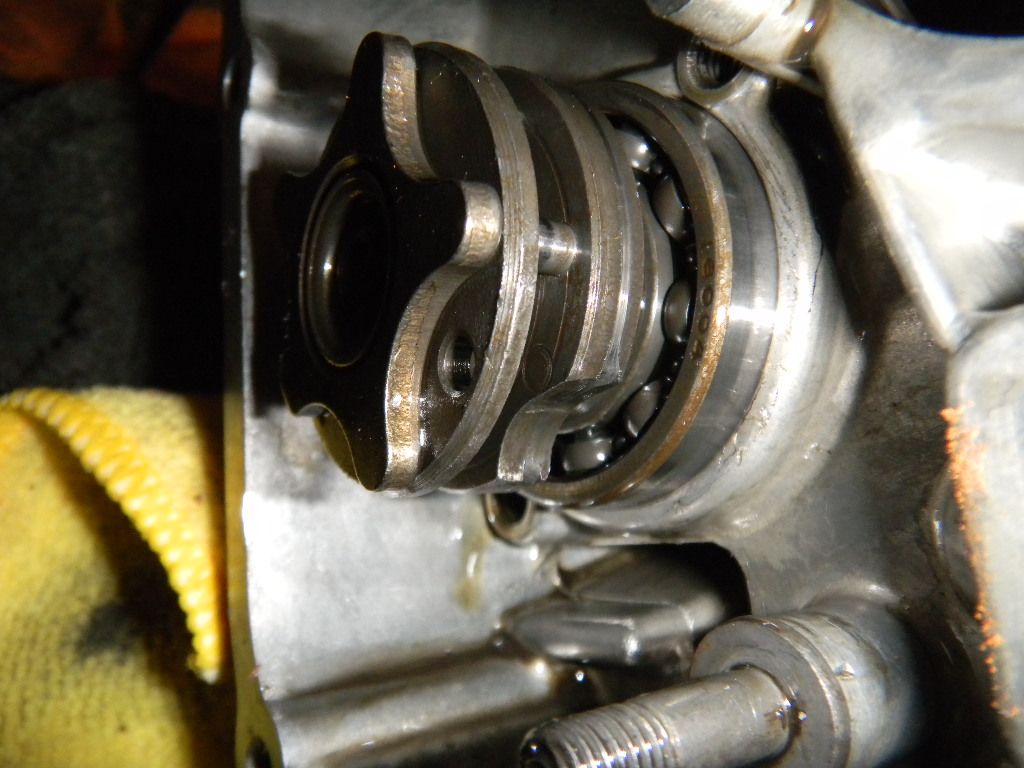

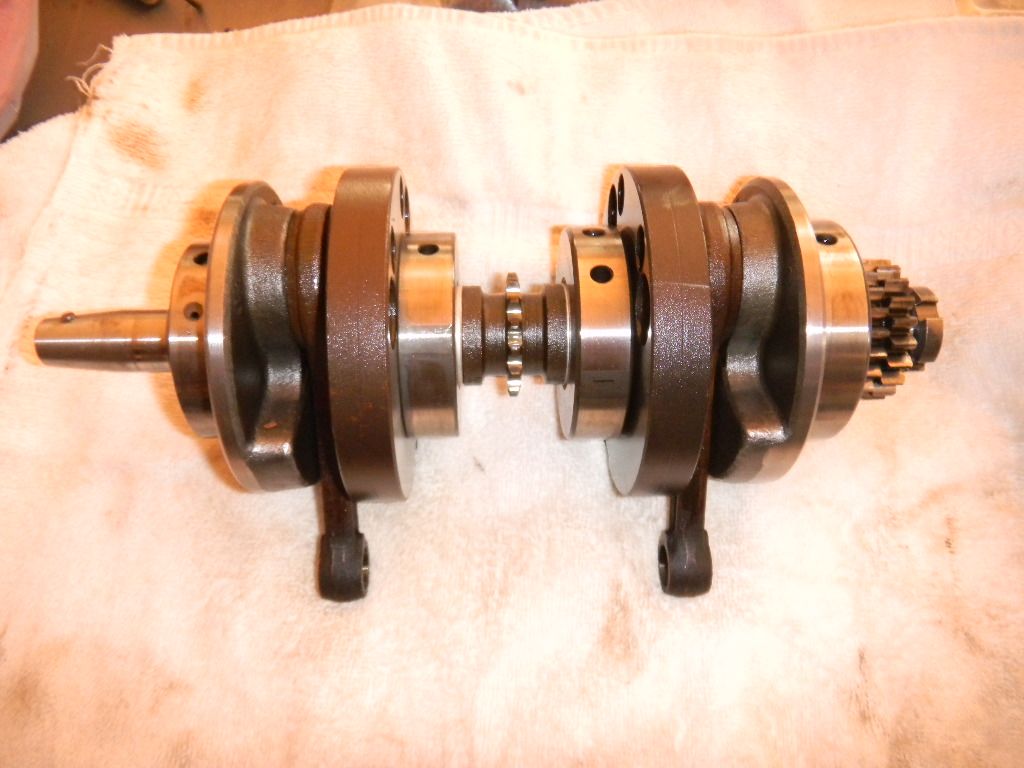

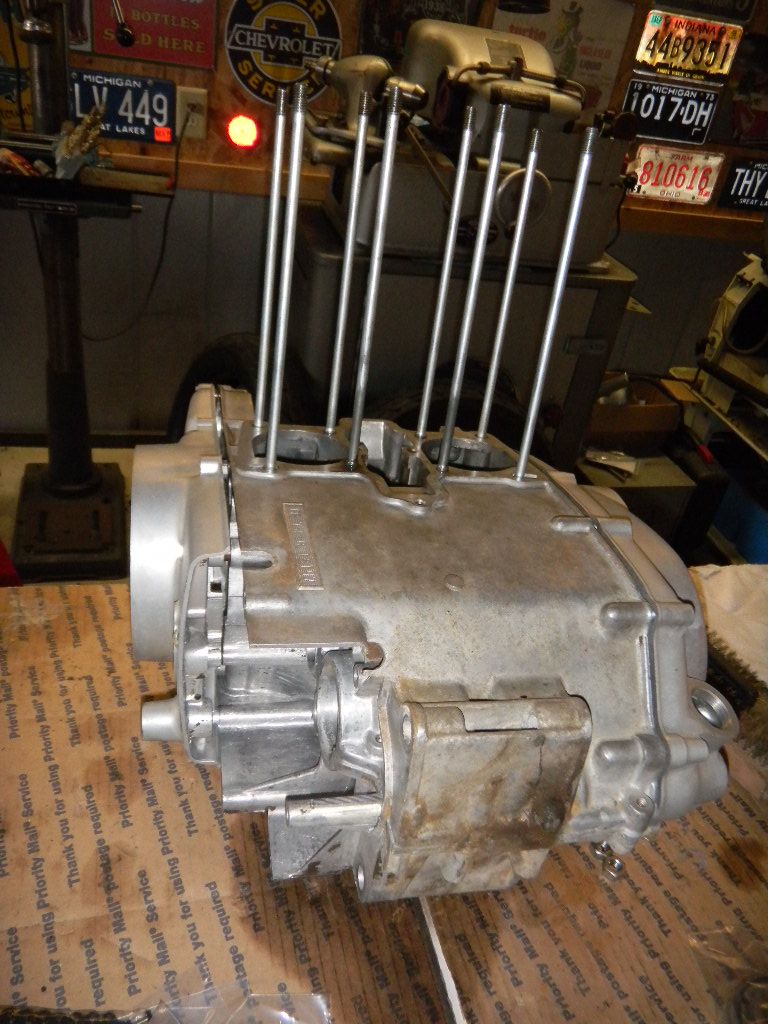

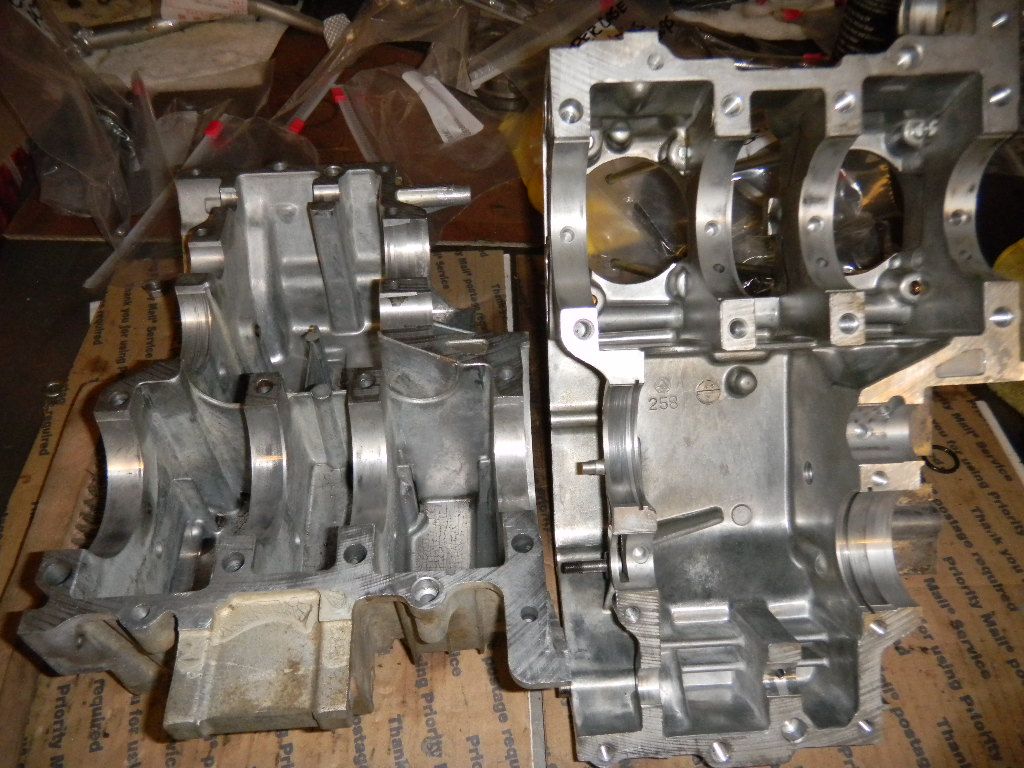

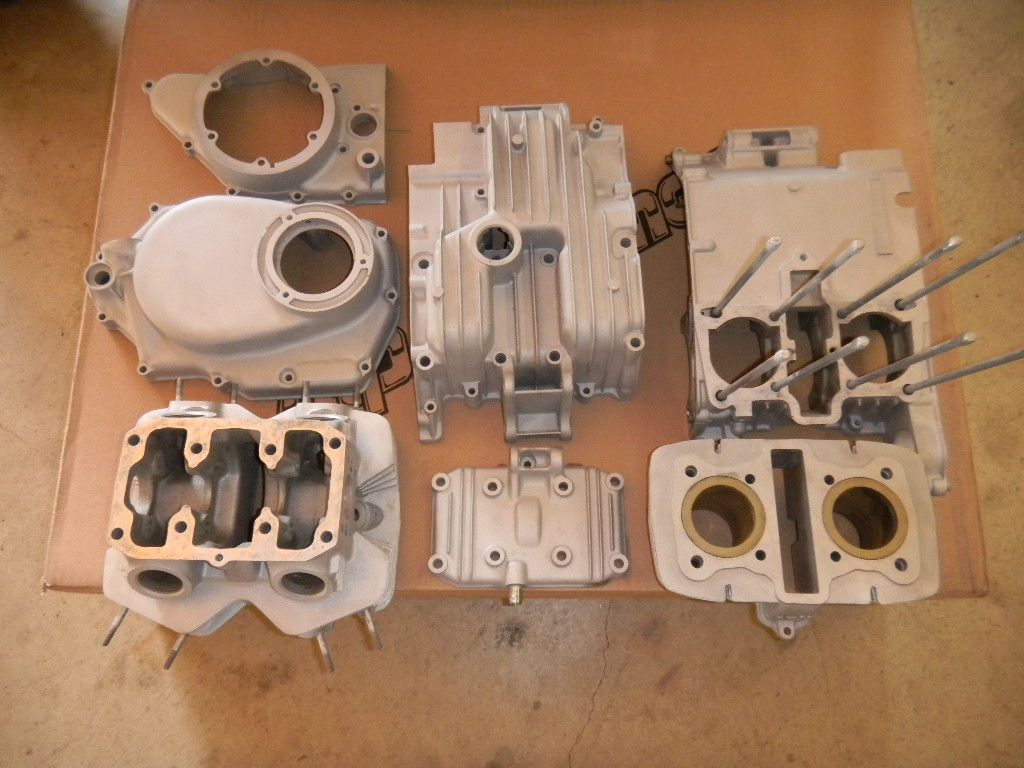

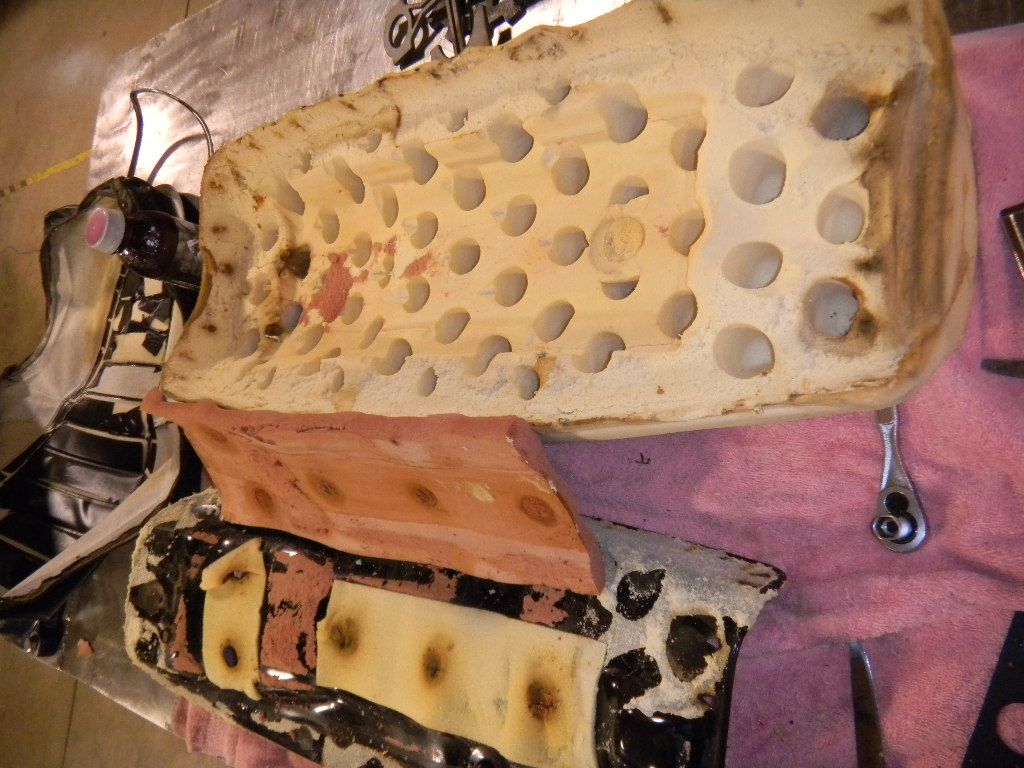

After about 2 hours of pulling & categorizing parts. Hope to have it down to the frame soon.

![Image]()

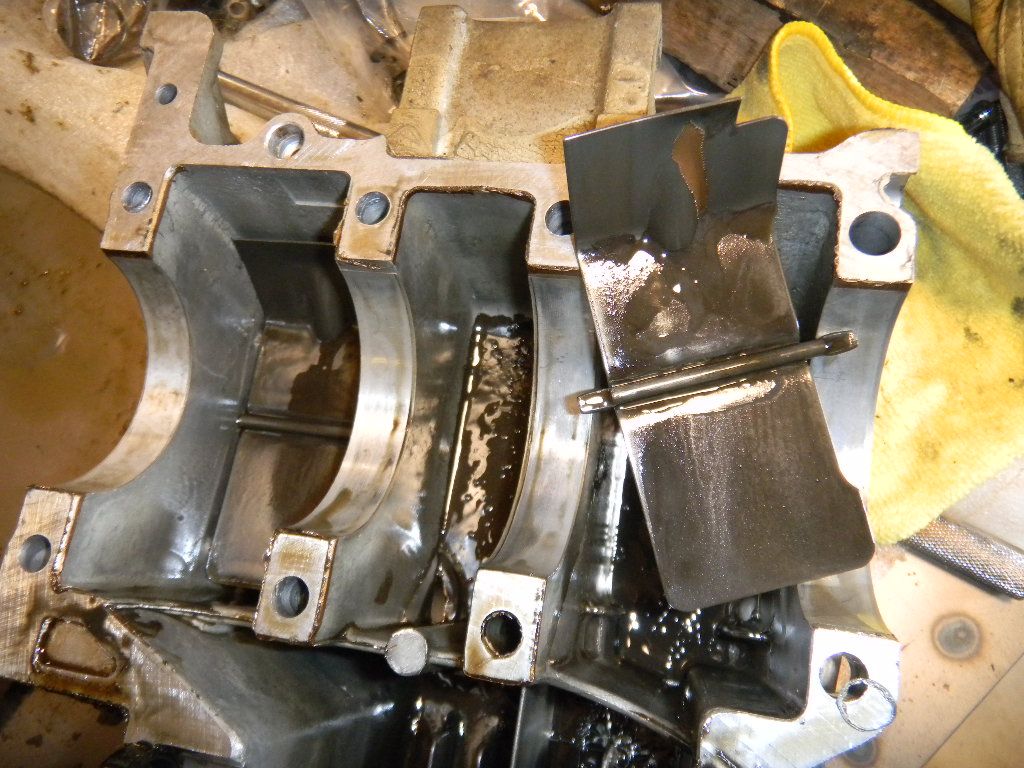

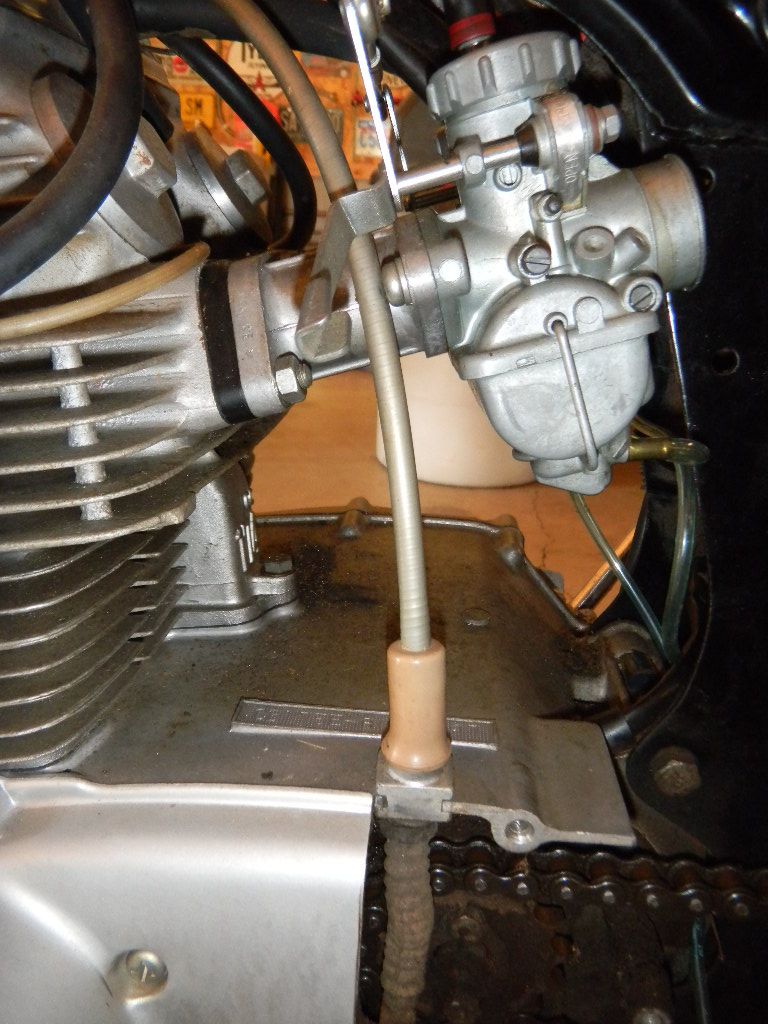

Carburetors were cleaned by the PO. The fuel tank is very corroded & rusted through in several places underneath, not sure I'll be able to save it.

![Image]()

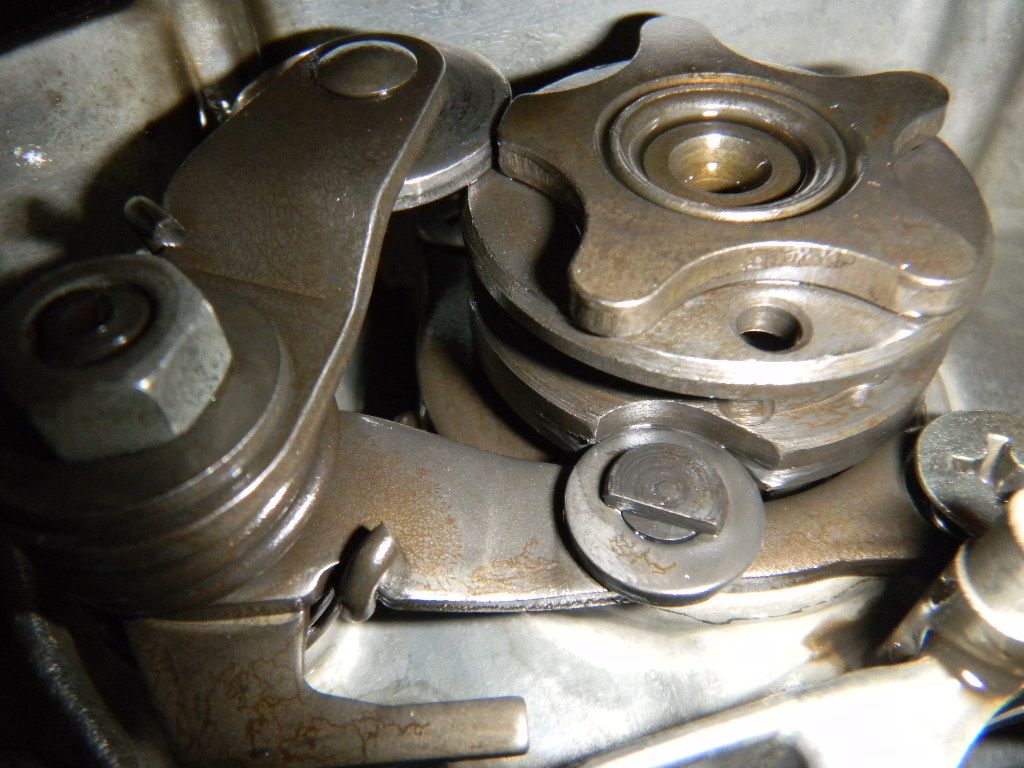

Exhaust are OEM NOS by the PO

![Image]()

I like Candy Blue, but Candy Ruby Red is the color of the '71 CB175 I had. We'll see which color wins out.

Questions...

- what brand of engine gasket sets are recommended and which one(s) should I stay away from?

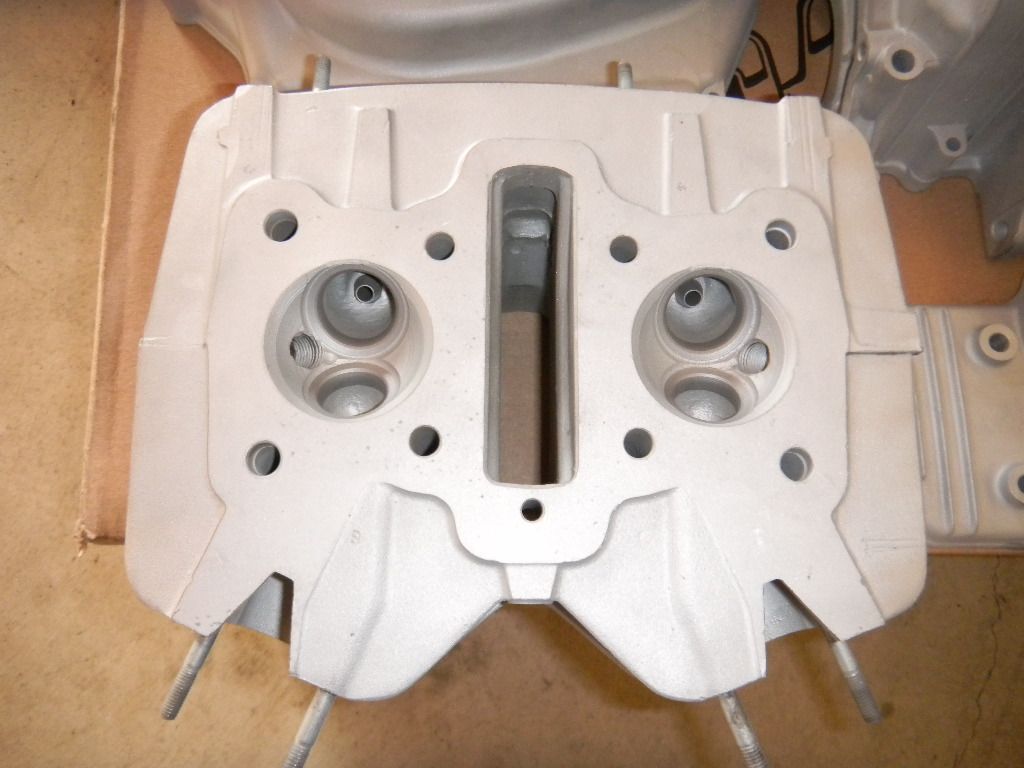

- I assume the engine was painted Honda Cloud Silver?

- where can I get a set of OEM tires (size and manufacturer)

Thanks!

Here she is just after I got it. Looks good from 20ft. Attempted to start it and ran on only the left cylinder. Corrected the stuck float valve on the right and it ran. Not good, but it ran

After about 2 hours of pulling & categorizing parts. Hope to have it down to the frame soon.

Carburetors were cleaned by the PO. The fuel tank is very corroded & rusted through in several places underneath, not sure I'll be able to save it.

Exhaust are OEM NOS by the PO

I like Candy Blue, but Candy Ruby Red is the color of the '71 CB175 I had. We'll see which color wins out.

Questions...

- what brand of engine gasket sets are recommended and which one(s) should I stay away from?

- I assume the engine was painted Honda Cloud Silver?

- where can I get a set of OEM tires (size and manufacturer)

Thanks!